LEADED TIN BRONZE 73-7-7-3 PLATE manufacturer in India, Saudi Arabia, UAE, South Africa, Qatar

جولة بار، عرافة بار، الجوف بار، ورود، مشرق المصنعة بار في المملكة العربية السعودية والإمارات العربية المتحدة

LEADED TIN BRONZE 73-7-7-3 PLATE manufacturer & ASTM B622 Bar, ASTM B619 Round Bar, ASTM B626 Bright Bar, ASTM B463 Hex Bar, ASTM F467 Hollow Bar, ASTM F468 Rod, ASTM B366 Round Bar, ASTM B473 Bar & ASTM B473 Rod suppliers

LEADED TIN BRONZE 73-7-7-3 PLATE, Round Bar & bright Bar Best Price in India, Mumbai, UAE, Saudi Arabia, South Africa, Qatar, جولة بار، عرافة بار، الجوف بار، ورود، مشرق المصنعة بار في المملكة العربية السعودية والإمارات العربية المتحدة

Chemical composition

AL |

SB | CU | FE | PB | NI | P | SI | S | SN | ZN | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Min/Max | 0.005 | 0.35 | 81.0 - 85.0 | 0.2 | 6.0 - 8.0 | 1 | 0.15 | 0.005 | 0.08 | 6.3 - 7.5 | 1.0 - 4.0 |

| Nominals | - | - | 83.0000 | - | 7.0000 | - | - | - | - | 6.9000 | 2.5000 |

| PRODUCT TYPE | TEMPER TYPE |

| Centrifugal | ASTM B271, SAE J462, J461 |

| Continuous | ASTM B505, SAE J461, J462 |

| Ingot | ASTM B30 |

| Prermanent | SAE J461, J462 |

| Sand | ASTM B584, B763, B66, SAE J462, J461 |

Mechanical properties

| TEMPER | SECT. SIZE | COLD WORK | TYPE MIN | TEMP | TENSILE STRENGTH | YS 0.05% UL |

YS 0.02% OFFSET |

YS 0.005% OFFSET |

ELONG. | RH B |

RH C |

RH F |

RH 30T |

VH 500 |

BH 500 |

BH 3000 |

SHEAR STRGTH |

FATIGUE STRGTH |

IZOD IMPACT STRGTH |

| - | in. | % | - | F | ksi | ksi | ksi | ksi | % | B | C | F | 30T | 500 | 500 | 3000 | ksi | ksi | ft-lb |

| - | mm. | - | - | C | MPa | MPa | MPa | MPa | - | - | - | - | - | - | - | - | MPa | MPa | J |

| As Centrifugal Cast | |||||||||||||||||||

| M02 | 68 | 30 | 14 | - | - | - | - | - | - | - | - | - | - | - | - | ||||

| M02 | 0 | SMIN | 20 | 207 | 97 | - | - | 15 | - | - | - | - | - | - | - | - | - | 0 | |

| As Continous Cast | |||||||||||||||||||

| M07 | 68 | 35 | 20 | - | - | - | - | - | - | - | - | - | - | - | - | ||||

| M07 | 0 | SMIN | 20 | 241 | 138 | - | - | 10 | - | - | - | - | - | - | - | - | - | 0 | |

| As Permanent Mold Cast | |||||||||||||||||||

| M05 | 68 | 30 | 14 | - | - | - | - | - | - | - | - | - | - | - | - | ||||

| M05 | 0 | TYP | 20 | 207 | 97 | - | - | 15 | - | - | - | - | - | - | - | - | - | 0 | |

| As Sand Cast | |||||||||||||||||||

| M01 | 68 | 35 | 18 | - | - | - | - | - | - | - | - | - | - | - | 16 | 6 | |||

| M01 | 0 | TYP | 20 | 241 | 124 | - | - | 20 | - | - | - | - | - | 65 | - | - | 110 | 8 |

Physical properties

| PRODUCT PROPERTY | US CUSTOMARY | METRIC |

| Coefficient of Thermal Expansion | 10.0 . 10-6 per oF (68-392 F) | 18.0 . 10-6 per oC (20-200 C) |

| Density | 0.322 lb/in3 at 68 F | 8.91 gm/cm3 @ 20 C |

| Electrical Conductivity | 12 %IACS @ 68 F | 0.07 MegaSiemens/cm @ 20 C |

| Electrical Resistivity | 85.9 ohms-cmil/ft @ 68 F | 14.29 microhm-cm @ 20 C |

| Melting Point - Liquidus | 1790 F | 977 C |

| Melting Point - Solidus | 1570 F | 854 C |

| Modulas of Elasticity in Tension | 14500 ksi | 100000 MPa |

| Specific Gravity | 8.91 | 8.91 |

| Specific Heat Capacity | 0.09 Btu/lb/oF at 68 F | 377.1 J/kg . oK at 293 K |

| Thermal Conductivity | 33.6 Btu . ft/(hr . ft2 . oF)at 68F | 58.2 W/m . oK at 20 C |

Fabrication

| JOINING TECHNIQUE | SUITABILITY |

| Brazing | Good |

| Coated Metal Arc Welding | Not Recommended |

| Gas Shielded Arc Welding | Not Recommended |

| Machinability Rating | 70 |

| Oxyacetylene Welding | Not Recommended |

| Soldering | Excellent |

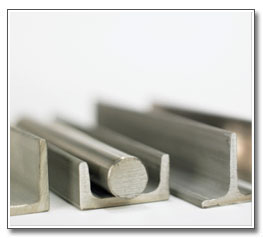

| Types of Bar | |||

| Alloy 20 Bar Rods Inconel Bar Rods Hastelloy Bar Rods Cupro Nickel Bar Rods Monel bar Nickel bar Nickel Alloy Bar Rods Copper Alloy Bar Rods |

Duplex Steel Bar Rods Carbon Steel Bar Rods Stainless Steel Bar Rods Round Bar Rods Cold Drawn Bar Rods Forged Round Bar Rods Bright Bar Rods SS Hexagonal Bar Rods |

Flat Bar Rods Square Bar Rods Black Bar Rods Triangle Bar Rods Hot Rolled Bar Rods 17 4ph Bar Rods 15 5ph Bar Rods 440c Bar Rods Our main markets for selling are: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LEADED TIN BRONZE 73-7-7-3 PLATE Sheet Exporters LEADED TIN BRONZE 73-7-7-3 PLATE Sheet Suppliers | LEADED TIN BRONZE 73-7-7-3 PLATE Sheet Stockist | LEADED TIN BRONZE 73-7-7-3 PLATE Sheet Mfrs Mumbai India, Saudi Arabiaجولة بار، عرافة بار، الجوف بار، ورود، مشرق المصنعة بار في المملكة العربية السعودية والإمارات العربية المتحدة |

|||