LEADED TIN BRONZE C93200 HOLLOW BAR manufacturer & ASTM B622 Bar, ASTM B619 Round Bar, ASTM B626 Bright Bar, ASTM B463 Hex Bar, ASTM F467 Hollow Bar, ASTM F468 Rod, ASTM B366 Round Bar, ASTM B473 Bar & ASTM B473 Rod suppliers

LEADED TIN BRONZE C93200 HOLLOW BAR, Round Bar & bright Bar Best Price in India, Mumbai, UAE, Saudi Arabia, South Africa, Qatar, جولة بار، عرافة بار، الجوف بار، ورود، مشرق المصنعة بار في المملكة العربية السعودية والإمارات العربية المتحدة

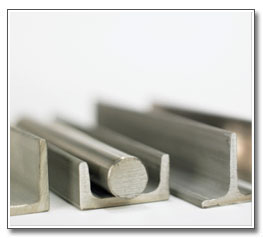

Bronze Hollow and Round Bars are available in following :

- Continuous Cast Hollow Bars : We stock a full range of Lg2 bronze hollow bars ranging from 7/8"x1/2" up to 12"x10". A great range of sizes are also stocked in Phosphorus and Aluminium bronze.

- Continuous Cast Solid Bars : We stock solid bars ranging from 1/2" to 10" diameter. Larger sizes are available with an approximate lead-time of 4 weeks. Our stock range will be increased over time in line with market demand.

- Lg2 Bronze Machined Bushes : We now carry a full range of Lg2 finished Machined Bronze Bushes. Our range is extensive and our stock levels are very high. We also produce special sizes to order including Flanged, Oil Grooved and Threaded.

Tin Bronzes:

- C90300 Cast Bronze Navy G

- C90500 Cast Tin Bronze, Gun Metal, SAE 62

- C90700 Cast Tin Bronze, SAE 65

- C91100 Cast Tin Bronze

High - Leaded Tin Bronzes :

- C93200 Cast Bearing Bronze, SAE 660

- C93500 Cast High Leaded Tin Bronze, SAE 66

- C93600 Cast Bearing Grade Bronze - MOD SAE 64

- C93700 Cast High Leaded Tin Bronze, SAE 64

- C93800 Cast High Leaded Tin Bronze, SAE 67

Leaded Tin Bronzes :

- C92200 Cast Leaded Tin Bronze, Navy M

- C92500 Cast Leaded Tin Bronze, SAE 640

- C92700 Cast Leaded Tin Bronze, SAE 63

Chemical composition

AL |

SB | CU | FE | PB | NI | P | SI | S | SN | ZN | |

| Min/Max | 0.005 | 0.35 | 81.0 - 85.0 | 0.2 | 6.0 - 8.0 | 1 | 0.15 | 0.005 | 0.08 | 6.3 - 7.5 | 1.0 - 4.0 |

| Nominals | - | - | 83.0000 | - | 7.0000 | - | - | - | - | 6.9000 | 2.5000 |

| PRODUCT TYPE | TEMPER TYPE |

| Centrifugal | ASTM B271, SAE J462, J461 |

| Continuous | ASTM B505, SAE J461, J462 |

| Ingot | ASTM B30 |

| Prermanent | SAE J461, J462 |

| Sand | ASTM B584, B763, B66, SAE J462, J461 |

Mechanical properties

| TEMPER | SECT. SIZE | COLD WORK | TYPE MIN | TEMP | TENSILE STRENGTH | YS 0.05% UL |

YS 0.02% OFFSET |

YS 0.005% OFFSET |

ELONG. | RH B |

RH C |

RH F |

RH 30T |

VH 500 |

BH 500 |

BH 3000 |

SHEAR STRGTH |

FATIGUE STRGTH |

IZOD IMPACT STRGTH |

| - | in. | % | - | F | ksi | ksi | ksi | ksi | % | B | C | F | 30T | 500 | 500 | 3000 | ksi | ksi | ft-lb |

| - | mm. | - | - | C | MPa | MPa | MPa | MPa | - | - | - | - | - | - | - | - | MPa | MPa | J |

| As Centrifugal Cast | |||||||||||||||||||

| M02 | 68 | 30 | 14 | - | - | - | - | - | - | - | - | - | - | - | - | ||||

| M02 | 0 | SMIN | 20 | 207 | 97 | - | - | 15 | - | - | - | - | - | - | - | - | - | 0 | |

| As Continous Cast | |||||||||||||||||||

| M07 | 68 | 35 | 20 | - | - | - | - | - | - | - | - | - | - | - | - | ||||

| M07 | 0 | SMIN | 20 | 241 | 138 | - | - | 10 | - | - | - | - | - | - | - | - | - | 0 | |

| As Permanent Mold Cast | |||||||||||||||||||

| M05 | 68 | 30 | 14 | - | - | - | - | - | - | - | - | - | - | - | - | ||||

| M05 | 0 | TYP | 20 | 207 | 97 | - | - | 15 | - | - | - | - | - | - | - | - | - | 0 | |

| As Sand Cast | |||||||||||||||||||

| M01 | 68 | 35 | 18 | - | - | - | - | - | - | - | - | - | - | - | 16 | 6 | |||

| M01 | 0 | TYP | 20 | 241 | 124 | - | - | 20 | - | - | - | - | - | 65 | - | - | 110 | 8 |

Physical properties

| PRODUCT PROPERTY | US CUSTOMARY | METRIC |

| Coefficient of Thermal Expansion | 10.0 . 10-6 per oF (68-392 F) | 18.0 . 10-6 per oC (20-200 C) |

| Density | 0.322 lb/in3 at 68 F | 8.91 gm/cm3 @ 20 C |

| Electrical Conductivity | 12 %IACS @ 68 F | 0.07 MegaSiemens/cm @ 20 C |

| Electrical Resistivity | 85.9 ohms-cmil/ft @ 68 F | 14.29 microhm-cm @ 20 C |

| Melting Point - Liquidus | 1790 F | 977 C |

| Melting Point - Solidus | 1570 F | 854 C |

| Modulas of Elasticity in Tension | 14500 ksi | 100000 MPa |

| Specific Gravity | 8.91 | 8.91 |

| Specific Heat Capacity | 0.09 Btu/lb/oF at 68 F | 377.1 J/kg . oK at 293 K |

| Thermal Conductivity | 33.6 Btu . ft/(hr . ft2 . oF)at 68F | 58.2 W/m . oK at 20 C |

Fabrication

| JOINING TECHNIQUE | SUITABILITY |

| Brazing | Good |

| Coated Metal Arc Welding | Not Recommended |

| Gas Shielded Arc Welding | Not Recommended |

| Machinability Rating | 70 |

| Oxyacetylene Welding | Not Recommended |

| Soldering | Excellent |

Standard Size

We offer a comprehensive range of hot rolled Steel Round Bar which is available in Mild Steel, High Yield Steel, Carbon Steel, Boron and Low Alloy Steel grades. Please use the table below to view our standard Steel Round Bar sizes. If you require non-standard round bar sizes, tolerances and/or grades please speak to us as these are manufactured and supplied subject to a minimum quantity by agreement.

| Rod/Bar Type | Sizes | Availability |

| LEADED TIN BRONZE C93200 HOLLOW BAR rod | 6mm |

|

| LEADED TIN BRONZE C93200 HOLLOW BAR rod | 8mm |

|

| LEADED TIN BRONZE C93200 HOLLOW BAR rod | 10mm |

|

| LEADED TIN BRONZE C93200 HOLLOW BAR rod | 12mm |

|

| LEADED TIN BRONZE C93200 HOLLOW BAR | 13mm |

|

| LEADED TIN BRONZE C93200 HOLLOW BAR | 16mm |

|

| LEADED TIN BRONZE C93200 HOLLOW BAR | 19mm |

|

| LEADED TIN BRONZE C93200 HOLLOW BAR | 22mm |

|

| LEADED TIN BRONZE C93200 HOLLOW BAR | 28mm |

|

| LEADED TIN BRONZE C93200 HOLLOW BAR | 40mm |

|

| LEADED TIN BRONZE C93200 HOLLOW BAR | 60mm |

|

| LEADED TIN BRONZE C93200 HOLLOW BAR | 75mm |

|

| LEADED TIN BRONZE C93200 HOLLOW BAR | 90mm |

|

| LEADED TIN BRONZE C93200 HOLLOW BAR | 120mm |

|

LEADED TIN BRONZE C93200 HOLLOW BAR Rod Karnataka | LEADED TIN BRONZE C93200 HOLLOW BAR Rod Orissa| LEADED TIN BRONZE C93200 HOLLOW BAR Rod Ahmedabad| LEADED TIN BRONZE C93200 HOLLOW BAR Rod Hyderabad| LEADED TIN BRONZE C93200 HOLLOW BAR Rod Tamil Nadu| LEADED TIN BRONZE C93200 HOLLOW BAR Rod Surat, LEADED TIN BRONZE C93200 HOLLOW BAR Rod Supply | LEADED TIN BRONZE C93200 HOLLOW BAR Rod Mfrs & stockist Exporters Mumbai India

You can choose a style of round bars you are looking for:

Round Bar - Stainless Steel

Round Bar - Extruded Aluminum

Round Bar - Cold Finished Carbon & Alloy

Round Bar - Brass

Round Bar- Copper

Round Bar- Drill Rod

Round Bar- Titanium

Round Bar- Hard Chrome Plated and IHCP

Round Bar- Precision Ground Linear Motion Shafting

Round Bars- Cold Drawn Aluminum

Application:

The most common shapes are round bar (also called rod), rectangular bar (including square bar, the special case of equal sides), and hexagonal bar (usually called hex bar for short). Tube and pipe are similar, but have hollow centers and are traditionally not called "bar" in industrial usage. (However, a product called hollow bar, essentially tube but with custom-orderable OD and ID and thus custom wall thickness, is marketed for lathe bar work which can benefit from obviation of drilling and rough boring.) Also similar in concept, but not called "bar", are the common structural shapes such as angle stock and channel stock. These are commonly available in steel and aluminum; the names "angle iron" and "channel iron" are still commonly used (informally) even though their literal namesake, wrought iron, has been replaced by steel and aluminum for most uses.