ALUMINIUM BRONZE PLATE C63200 manufacturer & ASTM B622 Bar, ASTM B619 Round Bar, ASTM B626 Bright Bar, ASTM B463 Hex Bar, ASTM F467 Hollow Bar, ASTM F468 Rod, ASTM B366 Round Bar, ASTM B473 Bar & ASTM B473 Rod suppliers

ALUMINIUM BRONZE PLATE C63200, sheet plate Best Price in India, Mumbai, UAE, Saudi Arabia, South Africa, Qatar, جولة بار، عرافة بار، الجوف بار، ورود، مشرق المصنعة بار في المملكة العربية السعودية والإمارات العربية المتحدة

Specifications

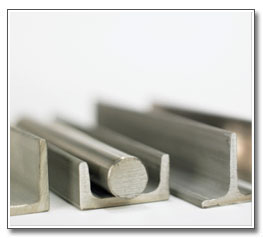

bronze aluminum plate

1.Thickness: 0.125mm to 3.75mm

2.Width: 36mm to 48mm

3.Customized sizes.

Nickel Aluminium Bronze Alloy Sheet

Aluminum bronze has high strength, wear resistance and excellent weldability. Aluminum bronze is very useful in a great number of engineering structures with a variety of the alloy finding applications in different industries.As an international manufacturer and supplier for Aluminum Bronze sheet, Shanghai Metal Corporation produces slitting, edging, and oscillate winding to fit your specific copper requirements.

Specifications of Aluminum Bronze Plate:

1. Grade: QAL9-4,QAL10-3-1.5,QAL10-4-4,C95400,C63200,C63000,CuAL10Fe3,CuAL11Fe5Ni5,C6 series,AB series,CAC series,CDA series,etc.

2. Chemical compostion: copper: 91.0%, Aluminum:7.0%, Iron: 2.0%, Zinc: 0.2%

3. Thickness: from 0.125mm to 3.75mm or customized according to your requirements

4. Width: from 36mm to 48mm or customized according to your requirements

5. Length: from 96mm to 120mm or customized according to your requirements

6. Average Physical Properties: Tensile 85,000 psi, Yield 35,000 psi, Elongation 42%, Brinell Hardness = 153

7. Standard: GB/T13808-1992,GB/T4423-2007,GB/T1176-1987,GB/T2040-2002,ASTM B150,ASTM B30,ASTB B103,ASTM B505,JIS H5111:1988,JIS H3250 : 1992,GOST 18175,EN 1982 : 1998,QJC,etc.

Component |

Wt. % |

Al |

6 - 7.5 |

Cu |

88.5 - 91.5 |

Fe |

2-3 |

Mn |

Max 0.1 |

Other |

Max 0.05 |

Pb |

Max 0.01 |

Sn |

0.02 - 0.5 |

Zn |

Max 0.05 |

Aluminium Bronze CA 104 (UNS C63200)

Technical Data Sheet

| Chemical Composition Limits | ||||

| Weight % | Cu | Al | Fe | Ni |

| CA 104 |

Rem | 8.5 / 11.0 | 4.0 / 5.5 | 4.0 / 5.5 |

CA 104 is a high strength material, combined with good resistance to oxidation and corrosion, especially in marine environments. Although other optional additions such as iron, nickel, manganese and silicon can be added for even greater corrosion resistance, strength and toughness properties.

Typical Mechanical Properties

| Material | 0.2% Proof Stress (N/mm² ) | Tensile Strength (N/mm² ) | Elongation % | Hardness (HV) |

| CA 104 | 420-500 | 720-820 | 25-15 | 200-240 |

Availability

CA 104 is available in Sheet, Strip, Plate, Rod, Bar and Forgings.

Specifications

DGS 8452

QQ-C-465

DTD 197A

BS 2872 (1989) Superceded by BS EN 12165 and BS EN 12420 (1998)

BS 2874 (1986) Superceded by BS EN 12167, BS EN 12163 and BS EN 12164 (1998)

DTD197A, BS B23, NES833 Pt2, NES834 Pt2, ISO 428 and DIN 17665

ASTM B150

UNS C63200

AMS 4640 and 4631

C630

CuAl10Ni5Fe4

WL 2.0966

ASNA 3406

Parameter of Aluminum Bronze Sheet:

(Customized sizes are accepted)

Size |

Thickness |

Size of sheet |

LBS/SQ FT |

LBS/Sheet |

0.063 |

- |

36 X 96 |

2.781 |

66.744 |

1/8 |

0.125 |

36 X 120 |

5.130 |

153.9 |

1/8 |

0.125 |

40 X 133 1/2 |

5.130 |

190.24 |

3/16 |

0.188 |

48 X 120 |

7.700 |

307.8 |

1/4 |

0.25 |

36 X 84 |

10.750 |

225.75 |

1/4 |

0.25 |

48 X 120 |

10.750 |

430 |

3/8 |

0.375 |

48 X 120 |

15.390 |

615.6 |

3/8 |

0.375 |

49 X 120 |

15.390 |

628.425 |

1/2 |

0.5 |

36 X 120 |

20.520 |

615.6 |

1/2 |

0.5 |

39 X 120 |

20.520 |

666.9 |

1/2 |

0.5 |

48 X 120 |

20.520 |

820.8 |

1/2 |

0.5 |

48 X 144 |

20.520 |

985 |

3/4 |

0.75 |

48 X 120 |

32.190 |

1231 |

3/4 |

0.75 |

48 X 144 |

32.190 |

1483 |

1 |

1.00 |

48 X 120 |

41.040 |

1641.6 |

1 ½ |

1.50 |

48 X 96 |

64.380 |

2060.16 |

1 ½ |

1.50 |

48 X 144 |

64.380 |

3090.24 |

2 |

2.00 |

48 X 72 |

86.000 |

2064 |

AnnealedSize |

YieldMPaStrengthmin. |

MPaUTSmin. |

Elongation% min. |

Up to25.4mm |

469 |

758 |

10 |

Over 25.4mm to50.8mm |

414 |

758 |

10 |

Over 50.8mm to76.2mm |

379 |

724 |

10 |

Heat Treatment:

Condition |

Tool Type |

CutDepth mm |

Speed m/min. |

Feedmm/rev. |

Annealed |

Carbide |

3.0– 6.0roughing |

30 – 60 |

0.25 |

0.12 – 0.25 finishing |

120– 180 |

0.12 |

Features:

•Excellent resistance to seawater corrosion;

•High intensity, up to 800MPa;

•High hardness, up to HB180;

•Good antifriction;

•Well finished and polished;

•Better operational life;

•Convenient handling;

•Mechanical properties are stable in the processing at 400 °C ambient temperature.

Applications:

•Bushings

•Bearings

•Gear parts

•Ship-building

•Fasteners

•Machinery

•Aviation

•Manufacturing sectors

•Wear Plates

•Structural Units in Process Equipment

•Vessels with High Pressure Requirements

•Heat Exchangers

•Cylinder Mold Tie Rods

•Ball Socket Seats

•Fasteners,etc.