LEADED TIN BRONZE C93200 PLATE manufacturer & ASTM B622 Bar, ASTM B619 Round Bar, ASTM B626 Bright Bar, ASTM B463 Hex Bar, ASTM F467 Hollow Bar, ASTM F468 Rod, ASTM B366 Round Bar, ASTM B473 Bar & ASTM B473 Rod suppliers

LEADED TIN BRONZE C93200 PLATE, Round Bar & bright Bar Best Price in India, Mumbai, UAE, Saudi Arabia, South Africa, Qatar, جولة بار، عرافة بار، الجوف بار، ورود، مشرق المصنعة بار في المملكة العربية السعودية والإمارات العربية المتحدة

C93200 Bearing Bronze (SAE660) - C932 Leaded Tin Bronze

CDA 93200, SAE 660, B505,

C93200 High Leaded Tin Bronze / Bearing Bronze has excellent machining properties, good hardness, strength and wear resistance with excellent anti-friction qualities. The alloy is not subject to dezincification and has reasonable corrosion resistance to seawater and brine making it suitable for pump and valve components. C93200 is suitable for bearings, bushings having medium loads and speeds with adequate lubrication.

Applications for C93200 High Leaded Tin Bronze / SAE 660 Bearing Bronze:

AUTOMOTIVE: Automotive Fittings

FASTENERS: Washers

INDUSTRIAL: Thrust Washers, Pumps, Bushings, Machine Parts, Main Spindle Bearings, Machine Tool Bearings, Bearings for Cranes, Trunion Bearings, Roll Neck Bearings, Rolling Mill Bearings, Linkage Bushings for Presses, Fuel Pump Bushings, Water Pump Bushings, Diesel Engine Wrist Pin Bushings, Forging Press Toggle Lever Bearings, Hydraulic Press Stuffing Box, Hydraulic Press Main Lining, Pump Impellers, General Purpose Bushings, Fittings, Pump Fixtures, Insert Bearings, Bearing

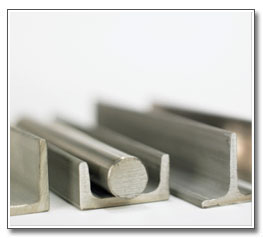

Sizes Available>

SOLID BAR: 3/8" - 16" diameter

HOLLOW BAR (Continuous Cast): 1/2" I.D. x 1" O.D. thru 14" I.D. x 16" O.D.

HOLLOW BAR (Centrifugal): up to 30" O.D. (stock) / 100" O.D. plus, special order

SQUARE BAR: up to 10" square

WEAR PLATE: 1/4" - 10 thick thru 18" widths

Chemical composition

AL |

SB | CU | FE | PB | NI | P | SI | S | SN | ZN | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Min/Max | 0.005 | 0.35 | 81.0 - 85.0 | 0.2 | 6.0 - 8.0 | 1 | 0.15 | 0.005 | 0.08 | 6.3 - 7.5 | 1.0 - 4.0 |

| Nominals | - | - | 83.0000 | - | 7.0000 | - | - | - | - | 6.9000 | 2.5000 |

| PRODUCT TYPE | TEMPER TYPE |

| Centrifugal | ASTM B271, SAE J462, J461 |

| Continuous | ASTM B505, SAE J461, J462 |

| Ingot | ASTM B30 |

| Prermanent | SAE J461, J462 |

| Sand | ASTM B584, B763, B66, SAE J462, J461 |

Mechanical properties

| TEMPER | SECT. SIZE | COLD WORK | TYPE MIN | TEMP | TENSILE STRENGTH | YS 0.05% UL |

YS 0.02% OFFSET |

YS 0.005% OFFSET |

ELONG. | RH B |

RH C |

RH F |

RH 30T |

VH 500 |

BH 500 |

BH 3000 |

SHEAR STRGTH |

FATIGUE STRGTH |

IZOD IMPACT STRGTH |

| - | in. | % | - | F | ksi | ksi | ksi | ksi | % | B | C | F | 30T | 500 | 500 | 3000 | ksi | ksi | ft-lb |

| - | mm. | - | - | C | MPa | MPa | MPa | MPa | - | - | - | - | - | - | - | - | MPa | MPa | J |

| As Centrifugal Cast | |||||||||||||||||||

| M02 | 68 | 30 | 14 | - | - | - | - | - | - | - | - | - | - | - | - | ||||

| M02 | 0 | SMIN | 20 | 207 | 97 | - | - | 15 | - | - | - | - | - | - | - | - | - | 0 | |

| As Continous Cast | |||||||||||||||||||

| M07 | 68 | 35 | 20 | - | - | - | - | - | - | - | - | - | - | - | - | ||||

| M07 | 0 | SMIN | 20 | 241 | 138 | - | - | 10 | - | - | - | - | - | - | - | - | - | 0 | |

| As Permanent Mold Cast | |||||||||||||||||||

| M05 | 68 | 30 | 14 | - | - | - | - | - | - | - | - | - | - | - | - | ||||

| M05 | 0 | TYP | 20 | 207 | 97 | - | - | 15 | - | - | - | - | - | - | - | - | - | 0 | |

| As Sand Cast | |||||||||||||||||||

| M01 | 68 | 35 | 18 | - | - | - | - | - | - | - | - | - | - | - | 16 | 6 | |||

| M01 | 0 | TYP | 20 | 241 | 124 | - | - | 20 | - | - | - | - | - | 65 | - | - | 110 | 8 |

Physical properties

| PRODUCT PROPERTY | US CUSTOMARY | METRIC |

| Coefficient of Thermal Expansion | 10.0 . 10-6 per oF (68-392 F) | 18.0 . 10-6 per oC (20-200 C) |

| Density | 0.322 lb/in3 at 68 F | 8.91 gm/cm3 @ 20 C |

| Electrical Conductivity | 12 %IACS @ 68 F | 0.07 MegaSiemens/cm @ 20 C |

| Electrical Resistivity | 85.9 ohms-cmil/ft @ 68 F | 14.29 microhm-cm @ 20 C |

| Melting Point - Liquidus | 1790 F | 977 C |

| Melting Point - Solidus | 1570 F | 854 C |

| Modulas of Elasticity in Tension | 14500 ksi | 100000 MPa |

| Specific Gravity | 8.91 | 8.91 |

| Specific Heat Capacity | 0.09 Btu/lb/oF at 68 F | 377.1 J/kg . oK at 293 K |

| Thermal Conductivity | 33.6 Btu . ft/(hr . ft2 . oF)at 68F | 58.2 W/m . oK at 20 C |

Fabrication

| JOINING TECHNIQUE | SUITABILITY |

| Brazing | Good |

| Coated Metal Arc Welding | Not Recommended |

| Gas Shielded Arc Welding | Not Recommended |

| Machinability Rating | 70 |

| Oxyacetylene Welding | Not Recommended |

| Soldering | Excellent |