ALUMINIUM BRONZE AB2 HOLLOW BAR manufacturer & ASTM B622 Bar, ASTM B619 Round Bar, ASTM B626 Bright Bar, ASTM B463 Hex Bar, ASTM F467 Hollow Bar, ASTM F468 Rod, ASTM B366 Round Bar, ASTM B473 Bar & ASTM B473 Rod suppliers

ALUMINIUM BRONZE AB2 HOLLOW BAR, Round Bar & bright Bar Best Price in India, Mumbai, UAE, Saudi Arabia, South Africa, Qatar, جولة بار، عرافة بار، الجوف بار، ورود، مشرق المصنعة بار في المملكة العربية السعودية والإمارات العربية المتحدة

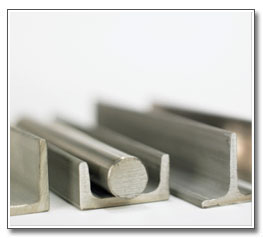

Aluminium Bronze Rods

| Aluminium Bronze | ||||||||

| CA102 (type) | CA102 | C61000 | 540-590 | 440-510 | 25-40 | |||

| CA103 | CA103 | C62300 | AMS 4635; | 520 | 215 | 22 | ||

| CA104 / BSB23 / DTD197A | CA104 | C63200 | CW307G | L14-706; AIR9070 UA 11N | 650-700 | 320-400 | 10-12 | |

| DEF STAN 02-833; NES 833 | DGS1043 | 620-680 | 245-325 | 17 | ||||

| COLSPEED 90® | C64110 | 700-760 | 400-500 | 10-13 | 200-220 | |||

| C61300 | CA106 | C61300 | 485-550 | 240-345 | 30 | |||

| C61900 | C61900 | 540-620 | 255-345 | 15-25 | ||||

| C62400 | C62400 | 620-655 | 275-310 | 10-12 | ||||

| C63000; AMS4640 | CA105 | C63000 | CW307G | NFL-14705 | 550-690 | 275-345 | 5-12 | |

| DEF STAN 02-834; NES834; C64200 | CA107 | C64200 | CW301G | DGS1044; AMS4631; |

Aluminium Bronze C95400 Hollow Bars

We offers the most popular of Aluminum Bronze alloys, providing high tensile and yield strength, good ductility, weldability and machinability, excellent resistance to wear, fatigue and deformation under shock and load. It exhibits excellent corrosion resistant properties. This alloy and most of the alloys in this family provide flexible mechanical properties with heat treatment and small additions of nickel. It’s used as gears, worm wheels, bushings, bearings, wear strips, valve bodies, valve seats and valve guides in chemical, marine, aircraft, machine tools and earth moving machinery.

Chemical Composition:

Cu: 83% Min

Fe: 3 to 5%

Al: 0 to 11.5%

Ni: 1.5% Max

Mn: 0.5% Max

Mexhanical Properties:

Tensile Strength: 586 Mpa Min

Yield Strength: 221 Mpa Min

Elongation : 10% Min

Aluminium Bronze C95210

APPLICATIONS:

Pump impellers, valves & underwater fittings. They can handle high velocities and properties remain

strong in elevated temperatures.

Aluminium Nickel Bronze AB2 C95810

Aluminium Nickel Bronze AB2 C95810 has good corrosion resistance and good wear resistance properties and is very high strength with high resistance to oxidation. It also possesses very good strength at elevated temperatures. It is typically used in the chemical, marine and oil operation where chemical and sea water are prevalent. Common applications are valve fittings, propellers, propeller shafts, heavy duty bearings, landing gear parts, gears, worm wheels, non-sparking tools, etc.

PROFILES

- Hollow Bar

-

Round Bar

TYPICAL MECHANICAL PROPERTIES

Al |

: 8.5% - 9.5% |

|

Fe |

: 3.5% - 4.5% |

Ni |

: 4.0% - 5.0% |

|

Pb |

: < 0.05% |

Mn |

: 0.8% - 1.5% |

|

Cu |

: > 79% |

* Tensile Strength |

min. MPa 590 |

* 0.2% Proof Stress |

min. MPa 240 |

* Elongation |

min. 15% |

* Brinell Hardness |

min. HB 140 |

Features:

- Corrosion resistance

- Tough structure

- Durability

Specifications:

- CA102

- C61000

- CuAl6Ni2

Nominal Composition Cu Rem, Al 6.0%, Ni 2.0% Mechanical Properties:

| Ultimate Tensile Strength N/mm² |

Proof Stress N/mm² |

Elongation % |

Hardness HB |

| 540-590 | 440-510 | 25-40 |

Details:

- Cold workable

- High strength

- Excellent corrosion resistance

- Attractive rich 18 carat gold colour

- High wear and abrasion resistance

Applications:

- Offshore & Marine: Decorative trim, marine hardware and sheathing

Specifications:

- CA102

- C61000

- CuAl6Ni2

Nominal Composition Cu Rem, Al 6.0%, Ni 2.0% Mechanical Properties:

| Ultimate Tensile Strength N/mm² |

Proof Stress N/mm² |

Elongation % |

Hardness HB |

| 540-590 | 440-510 | 25-40 |

Key Features:

- Cold workable

- High strength

- Excellent corrosion resistance

- Attractive rich 18 carat gold colour

- High wear and abrasion resistance

Standard Size

We offer a comprehensive range of hot rolled Steel Round Bar which is available in Mild Steel, High Yield Steel, Carbon Steel, Boron and Low Alloy Steel grades. Please use the table below to view our standard Steel Round Bar sizes. If you require non-standard round bar sizes, tolerances and/or grades please speak to us as these are manufactured and supplied subject to a minimum quantity by agreement.

| Rod/Bar Type | Sizes | Availability |

| ALUMINIUM BRONZE AB2 HOLLOW BAR rod | 6mm |

|

| ALUMINIUM BRONZE AB2 HOLLOW BAR rod | 8mm |

|

| ALUMINIUM BRONZE AB2 HOLLOW BAR rod | 10mm |

|

| ALUMINIUM BRONZE AB2 HOLLOW BAR rod | 12mm |

|

| ALUMINIUM BRONZE AB2 HOLLOW BAR | 13mm |

|

| ALUMINIUM BRONZE AB2 HOLLOW BAR | 16mm |

|

| ALUMINIUM BRONZE AB2 HOLLOW BAR | 19mm |

|

| ALUMINIUM BRONZE AB2 HOLLOW BAR | 22mm |

|

| ALUMINIUM BRONZE AB2 HOLLOW BAR | 28mm |

|

| ALUMINIUM BRONZE AB2 HOLLOW BAR | 40mm |

|

| ALUMINIUM BRONZE AB2 HOLLOW BAR | 60mm |

|

| ALUMINIUM BRONZE AB2 HOLLOW BAR | 75mm |

|

| ALUMINIUM BRONZE AB2 HOLLOW BAR | 90mm |

|

| ALUMINIUM BRONZE AB2 HOLLOW BAR | 120mm |

|

ALUMINIUM BRONZE AB2 HOLLOW BAR Rod Karnataka | ALUMINIUM BRONZE AB2 HOLLOW BAR Rod Orissa| ALUMINIUM BRONZE AB2 HOLLOW BAR Rod Ahmedabad| ALUMINIUM BRONZE AB2 HOLLOW BAR Rod Hyderabad| ALUMINIUM BRONZE AB2 HOLLOW BAR Rod Tamil Nadu| ALUMINIUM BRONZE AB2 HOLLOW BAR Rod Surat, ALUMINIUM BRONZE AB2 HOLLOW BAR Rod Supply | ALUMINIUM BRONZE AB2 HOLLOW BAR Rod Mfrs & stockist Exporters Mumbai India

You can choose a style of round bars you are looking for:

Round Bar - Stainless Steel

Round Bar - Extruded Aluminum

Round Bar - Cold Finished Carbon & Alloy

Round Bar - Brass

Round Bar- Copper

Round Bar- Drill Rod

Round Bar- Titanium

Round Bar- Hard Chrome Plated and IHCP

Round Bar- Precision Ground Linear Motion Shafting

Round Bars- Cold Drawn Aluminum

Application:

The most common shapes are round bar (also called rod), rectangular bar (including square bar, the special case of equal sides), and hexagonal bar (usually called hex bar for short). Tube and pipe are similar, but have hollow centers and are traditionally not called "bar" in industrial usage. (However, a product called hollow bar, essentially tube but with custom-orderable OD and ID and thus custom wall thickness, is marketed for lathe bar work which can benefit from obviation of drilling and rough boring.) Also similar in concept, but not called "bar", are the common structural shapes such as angle stock and channel stock. These are commonly available in steel and aluminum; the names "angle iron" and "channel iron" are still commonly used (informally) even though their literal namesake, wrought iron, has been replaced by steel and aluminum for most uses.