PHOSPHOR BRONZE PB1 HOLLOW BAR manufacturer & ASTM B622 Bar, ASTM B619 Round Bar, ASTM B626 Bright Bar, ASTM B463 Hex Bar, ASTM F467 Hollow Bar, ASTM F468 Rod, ASTM B366 Round Bar, ASTM B473 Bar & ASTM B473 Rod suppliers

PHOSPHOR BRONZE PB1 HOLLOW BAR, Round Bar & bright Bar Best Price in India, Mumbai, UAE, Saudi Arabia, South Africa, Qatar, جولة بار، عرافة بار، الجوف بار، ورود، مشرق المصنعة بار في المملكة العربية السعودية والإمارات العربية المتحدة

We are suppliers of phosphor bronze in round bar and hollow bar / tube. Specifications are available conforming to British (BS), ASTM, UNS and European standards.

Bronze

| Bronze is the oldest alloy known to man. It is an alloy of copper and tin but it is more often used with other alloying elements included. Bronze has found a wide variety of used over the years but other materials have replaced it in some instances. Bronze still, however, finds many uses in bearings, gears and electronic applications. |

Commonly stocked in grade BS1400 PB1 and PB102 with other less common grades also available. Continuous cast production gives characterisitcs of high density, close grain structure with good mechanical and machining properties.

With a lower tensile strength than phosphor bronze free machining leaded bronze is available in grades LG2 and SAE660.

The basics

Strictly speaking, bronze is an alloy of copper and tin. However, bronze is also used to describe a wider range of copper based alloys. Generally, bronze alloys consist of about 12% tin, though some specialised products may contain much as 20%. Phosphor bronzes, which contain less than 8% tin, have an addition of phosphor to improve strength and hardness.

Superior attributes can often be attained through the addition of other elements to the basic bronze alloy. As well as phosphor, zinc and lead are the most common additions.

Bronze alloys

A leaded bronze will generally have better machining characteristics than an unleaded bronze. It will, however, retain a plasticity that makes it ideal for applications such as the production of bearings, as it allows slacker tolerances to be absorbed if softer shaft materials are used. This also prevents the overheating and seizure of like metals caused by friction.

Adding zinc to bronze alloys results in an alloy commonly known as “gunmetal”. This derives from the use of this product in early culverins etc., used because of its hardness and strength. It also has good resistance to corrosion and finds many applications in the marine industry. Added lead improves the machinability of this product.

Aluminium bronze, one of the newer additions to the alloy range, has become well established in the manufacturer of avionic equipment as well as use in naval and military applications.

Alloy specifications

During the late 1990s a new series of BS EN standards was brought in for all copper based alloys (i.e. bronze). The new series of standards brought with it a new system for describing products.

The system described products in two ways, one using symbols the other using numbers. The symbol system follows the ISO compositional system and a brass made up of a 63/37 ratio of copper and zinc is shown as CuZn37.

The numbering system is six-character alpha numeric system with two characters (the first of which will be ‘C’ for copper) followed by three numbers and a letter. Using this system PB1 has become CC481. with the second C denoting a cast product.

This catalogue displays the old and the new systems (including the symbol based new method).

Alloy selection

| BSB23 (DTD197) | CC481 (PB1) | CW451 (PB102) |

| C932 (SAE660) | CC494 (LB4C) | NES833 |

Phosphor Bronze Bronze – PB1 Solid bars & Cored Bars

Pre-Machined BS 1400: 1985: PB1

Form of Supply:

Solid Bars: cast 13 inch lengths

Cored Bars: cast 13 inch lengths

Tolerances:

Solid Bars

Nominal size + 0.020” (0.50mm).

Cored Bars

Nominal size + 0.020” (0.50mm) on O.D.

Nominal size – 0.030” (0.75mm) on I.D.

Stocked sizes Imperial (ins)

Solid Rounds Pre-machined

5/8, 3/4, 7/8, 1, 1.1/4, 1.1/2, 1.3/4, 2, 2.1/2, 3 and 4

Cored Rounds Pre-machined

| 1 x 3/4 | 1.1/2 x 3/4 | 1.3/4 x 3/4 | 2 x 1 | 2.1/2 x 1.1/2 | 3 x 1 | 4 x 1 | 5 x 3 |

| 1.3/4 x 1 | 2 x 1.1/2 | 3 x 1.1/2 | 4 x 2.1/2 | ||||

| 1.3/4 x 1.1/4 |

Standard Size

We offer a comprehensive range of hot rolled Steel Round Bar which is available in Mild Steel, High Yield Steel, Carbon Steel, Boron and Low Alloy Steel grades. Please use the table below to view our standard Steel Round Bar sizes. If you require non-standard round bar sizes, tolerances and/or grades please speak to us as these are manufactured and supplied subject to a minimum quantity by agreement.

| Rod/Bar Type | Sizes | Availability |

| PHOSPHOR BRONZE PB1 HOLLOW BAR rod | 6mm |

|

| PHOSPHOR BRONZE PB1 HOLLOW BAR rod | 8mm |

|

| PHOSPHOR BRONZE PB1 HOLLOW BAR rod | 10mm |

|

| PHOSPHOR BRONZE PB1 HOLLOW BAR rod | 12mm |

|

| PHOSPHOR BRONZE PB1 HOLLOW BAR | 13mm |

|

| PHOSPHOR BRONZE PB1 HOLLOW BAR | 16mm |

|

| PHOSPHOR BRONZE PB1 HOLLOW BAR | 19mm |

|

| PHOSPHOR BRONZE PB1 HOLLOW BAR | 22mm |

|

| PHOSPHOR BRONZE PB1 HOLLOW BAR | 28mm |

|

| PHOSPHOR BRONZE PB1 HOLLOW BAR | 40mm |

|

| PHOSPHOR BRONZE PB1 HOLLOW BAR | 60mm |

|

| PHOSPHOR BRONZE PB1 HOLLOW BAR | 75mm |

|

| PHOSPHOR BRONZE PB1 HOLLOW BAR | 90mm |

|

| PHOSPHOR BRONZE PB1 HOLLOW BAR | 120mm |

|

PHOSPHOR BRONZE PB1 HOLLOW BAR Rod Karnataka | PHOSPHOR BRONZE PB1 HOLLOW BAR Rod Orissa| PHOSPHOR BRONZE PB1 HOLLOW BAR Rod Ahmedabad| PHOSPHOR BRONZE PB1 HOLLOW BAR Rod Hyderabad| PHOSPHOR BRONZE PB1 HOLLOW BAR Rod Tamil Nadu| PHOSPHOR BRONZE PB1 HOLLOW BAR Rod Surat, PHOSPHOR BRONZE PB1 HOLLOW BAR Rod Supply | PHOSPHOR BRONZE PB1 HOLLOW BAR Rod Mfrs & stockist Exporters Mumbai India

You can choose a style of round bars you are looking for:

Round Bar - Stainless Steel

Round Bar - Extruded Aluminum

Round Bar - Cold Finished Carbon & Alloy

Round Bar - Brass

Round Bar- Copper

Round Bar- Drill Rod

Round Bar- Titanium

Round Bar- Hard Chrome Plated and IHCP

Round Bar- Precision Ground Linear Motion Shafting

Round Bars- Cold Drawn Aluminum

Application:

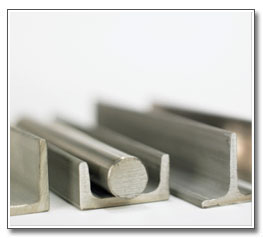

The most common shapes are round bar (also called rod), rectangular bar (including square bar, the special case of equal sides), and hexagonal bar (usually called hex bar for short). Tube and pipe are similar, but have hollow centers and are traditionally not called "bar" in industrial usage. (However, a product called hollow bar, essentially tube but with custom-orderable OD and ID and thus custom wall thickness, is marketed for lathe bar work which can benefit from obviation of drilling and rough boring.) Also similar in concept, but not called "bar", are the common structural shapes such as angle stock and channel stock. These are commonly available in steel and aluminum; the names "angle iron" and "channel iron" are still commonly used (informally) even though their literal namesake, wrought iron, has been replaced by steel and aluminum for most uses.