Inconel 601 Round Bar Rod Manufacturers Suppliers in India

ASTM B166 Inconel Alloy 601 Round Bar Suppliers, extensive stocks of Bar, Round Bar, Rod, Hex Bar, Flat Bar, Angles, Tee bar,Bright Round Bar, Square Bar, hexagon bar, Bright flat bar, Peeled & Polished Bar, Hexangular Bar/Rod, Roll Bar, Cold Rolled Bright Bar, Triangle Bar, shaped bar, Bright Bar,Inconel DIN 2.4816 Hex Bar,Alloy 601 Cold Finished Bar Supplier in India

Inconel 601 Bar, Inconel 601 Round Bar,Inconel 601 Round Bar Suppliers,Inconel 601 Bar suppliers , Inconel 601 Bright Bar, Inconel 601 Square Bar, Inconel 601 Hex Bar, Inconel 601 Flat Bar, Inconel 601 Black Bar, Inconel 601 Threaded Bar, Inconel 601 Forged Bar, Inconel 601 Rod,ASTM B166 Inconel UNS N06601 Round Bar,Inconel 601 Flat Bar Exporter,601 Square Bar Leading Manufacturer

Nido Metals is an ISO 9001:2008 certified Manufacturer and Suppliers of finished steel bright bars in the domestic as well as Global market. Since 1982 the company has the most elaborate and sophisticated manufacturing infrastructure to produce cold drawn ASTM B166 Inconel 601 Round Bars & Wires, We have a Production capacity of 6000 MT of HIGH PRECISION QUALITY STEEL BRIGHT BARS in different grades, sizes & sections.

The company plant is equipped with a range of machines and advanced processing facilities that give tremendous flexibility to meet the exact needs of our clients.

The company is the foremost producer of Bright bars in India which compare with the finest in the world. We process almost all popular grades in various national and International specifications.we are producing Bright Steel Bars in a variety of shapes and sizes according to various specifications of steel, and conforming to BSS, EN series, SAE, ISI, DIN, AISI.

Inconel Alloy 601 Round Bars Specification

Length : 100 mm To 3000 mm Long & Above

Finish : Bright, Polish & Black

Grade : Inconel 601 – UNS N06601

Form : Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc.

Our Inconel 601 Round Bars conforms to NACE MR0175/ISO 15156

Specification : ASTM B 166 / ASME SB 166, AMS 5715, DIN 17752, DIN 17753, DIN 17754, EN10095, ISO9723, ISO 9724, ISO 9725

Dimensions : ASTM, ASME and API

Size : 5 mm To 500 mm Dia in 100 mm TO 6000 mm Length available with NACE MR 01-75.

Diameter : 0.1 mm to 100 mm

| STANDARD | UNS | BS | EN | WERKSTOFF NR. | GOST | JIS | OR | AFNOR |

| Inconel 601 | N06601 | NA 49 | NiCr23Fe | 2.4851 | XH60BT | NCF 601 | ЭИ868 | NC23FeA |

| Grade | DIN | UNS |

| Inconel 601 | 2.4851 | N06601 |

| Standards | Designation |

| ASTM | B 166 |

| ASME | SB 166 |

| Standards | Inconel 601 |

| UNS | N06601 |

| Werkstoff Nr. | 2.4851 |

601 Inconel Alloy Round Bars Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

ASTM B166 Inconel 601 Bars Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Inconel 601 | 2.4851 | N06601 | XH60BT | NC23FeA | NCF 601 | NA 49 | NiCr23Fe | ЭИ868 |

Inconel Alloy 601 Round, Bright, Hex, Threaded Bar Chemical Composition

| Grade | Ni | Cr | Fe | C | Mn | S | Si | Cu |

| Inconel 601 | 58.0 - 63.0 | 21.0 -25.0 | Balance | 0.10 max | 1.0 max | 0.015 max | 0.5 max | 1.0 max |

Mechanical & Physical Properties of ASTM B166 Inconel 601 Round Bars

| Density | 8.1 g/cm3 |

| Melting Point | 1411 °C (2571 °F) |

| Tensile Strength | Psi – 80,000 , MPa – 550 |

| Yield Strength (0.2%Offset) | Psi – 30,000 , MPa – 205 |

| Elongation | 30 % |

ASTM B166 Inconel 601 Round Bars Chemical Composition

| Inconel 601 | |

| Ni | 58.0 – 63.0 |

| Cr | 21.0 – 25.0 |

| Fe | Balance |

| Al | 1.0 – 1.7 |

| C | 0.10 max |

| Mn | 1.0 max |

| S | 0.015 max |

| Si | 0.5 max |

| Cu | 1.0 max |

Types Of Available Products AISI, ASTM, DIN, ASME Inconel 601 Round Bars Live Inventory

» ASTM B166 Inconel Alloy 601 Rods Manufacturer

» B166 Inconel 601 Polish Bars Manufacturer

» Inconel Alloy 601 Black Bars Distributors

» Top Quality High Inconel 601 Alloy Spring Steel Bars

» Inconel Alloy 601 Rods

» Inconel 601 Round Bars

» ASTM B166 Inconel 601 Bars

» Inconel UNS N06601 Round Bars

» Alloy 601 Bright Bar Exporter

» ASME SB 166 Inconel 601 Forged Round Bars

» Inconel 601 Alloy Hexagon Bars Dealers

» Inconel UNS N06601 Cold Drawn Bars Stockholder

» High Speed Steel Inconel 601 Hollow Bar Suppliers

» DIN,EN,ASTM,ASME Inconel Alloy 601 Flat Bars

» 601 Inconel Threaded Bars Stockiest in India

» Inconel Alloy 601 Cold Drawn & Polished Square Bars

» Austenitic ASTM Bright 601 Alloy Inconel Bar

» Inconel WERKSTOFF NR. 2.4851 Round Bars

» Inconel 601 Alloy Round Bar

» Cold Rolled Inconel Alloy 601 Rods

Type of Inconel 601 Bar (Buy anything in Bar & Rod) | ||||

| Inconel 601 Round Bar | Inconel 601 Bright Bar | Inconel 601 Square Bar | Inconel 601 Hex Bar | Inconel 601 Rectangle Bar |

| Inconel 601 Flat Bar | Inconel 601 Black Bar | Inconel 601 Threaded Bar | Inconel 601 Forged Bar | Inconel 601 Rod |

Why Buy a Full Bar When You Just Need a Small Volume?

Nido Metals started its business in the manufacturing of round bars, and gradually evolved to various categories of steel products which currently includes Inconel 601 Bar, steel bars, Round Bar, Bright Bar, Square Bar, Hex Bar, Flat Bar, Rectangular Bar,Black Bar, Threaded Bar, Forged Bar, Rod and etc. The Company is built on the platform of highly committed staff team that always set the precise momentum to be ever ready in attaining the next level of success. The Company places strong ocmmitments towards customer satisfaction through product excellence, reliable quality, and competitive pricing.

Inconel 601 Bar specification

| Inconel 600 Bar (Rod) & Wire | |||||

| Sr. No. | Material | Diameter | Length | Specification | Manufacturer |

| 1 | Cupro Nickel Hastelloy Nickel Monel Inconel Alloy 20 Duplexl | 0.1 mm to 100 mm | 100 mm to 3000 mm Long & Above | ASTM BS DIN | |

| Note:- | |

| Nickel Alloy In Grade | Cupro Nickel (90/10, 70/30) Hastelloy (C-4, C-22, C276, B-2), Nickel (200 / 201 / 205), Monel (K400 & K500), Inconel (600, 601, 625 & 825), Incolloy (800, 800H), Alloy 20, Titanium, Tungston, Moly, Kanthal, Nimonic Nichrome (80:20), Ferro Nickel Alloy (55/45, 60/40, 70/30), Cobalt, Sanicro (28, SS 904L) Etc. |

| Bar In Form of | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wiremesh, Billet, Ingot, Forging, Casting Etc. |

| Value Added Service | Forging, Rolling, Machining (CNC), Heat Treatment, Cutting Etc. |

| Test Certificate | Laboratory Test Certificate from Government Approved Lab. Manufacturer Test Certificate |

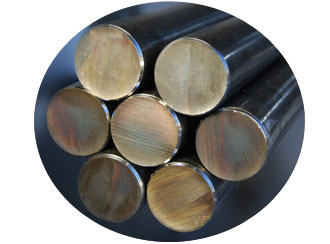

Inconel 601 Round Bar

| Manufacturer | Dealer | Supplier | Stockist | Distributor Trade Name: Inconel 601 Bar Round bar weight calculationsMost common hot selling Round Bar grades include:

Test Certificate

|

Inconel 601 Bright Bar

| Manufacturer | Dealer | Supplier | Stockist | Distributor Trade Name: Inconel 601 Bar Most common hot selling Bright Bar grades include:

Test Certificate

|

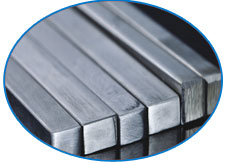

Inconel 601 Square Bar

| Manufacturer | Dealer | Supplier | Stockist | Distributor Trade Name: Inconel 601 Bar Square bar weight calculatorMost common hot selling Square Bar grades include:

Test Certificate |

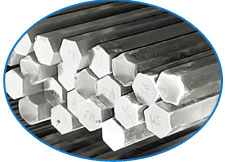

Inconel 601 Hex Bar

|

Trade Name: Inconel 601 Bar Most common hot selling Hex Bar grades include:

Test Certificate |

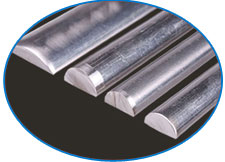

Inconel 601 Rectangle Bar / Rectangular Bar

|

Trade Name: Inconel 601 Bar Most common hot selling Rectangle Bar grades include:

Test Certificate |

Inconel 601 Flat Bar

|

Standard : ASTM B 166, ASTM B 160, ASTM B 164, ASTM B 446, ASTM B 637, ASTM B 408, ASTM B 425, ASTM B 574, ASTM B 335, ASTM B 473, ASTM B 649 Flat bar weight calculatorMost common hot selling Flat Bar grades include:

Test Certificate

|

Inconel 601 Black Bar

|

Trade Name: Inconel 601 Bar Most common hot selling Black Bar grades include:

Test Certificate |

Inconel 601 Threaded Bar

|

Trade Name: Inconel 601 Bar Most common hot selling Threaded Bar grades include:

Test Certificate |

Inconel 601 Forged Bar

|

Trade Name: Inconel 601 Bar Most common hot selling Forged Bar grades include:

Test Certificate |

Inconel 601 Rod

|

Trade Name: Inconel 601 Bar Most common hot selling Rod grades include:

Test Certificate |

Inconel 601 Bar leading manufacturers

We are distributor, dealer & supplier of Outokumpu round bar, Stainless steel bar, Thyssenkrupp round bar, Steel bar, Mukand Ltd Round Bar. You can also download the PDF file of Outokumpu stainless steel bar sizes and specifications, Outokumpu stainless steel bar brochure, Stainless Steel Bar and Long Products, European Stainless Bar and A Machining Comparison between Outokumpu PRODEC® and Standard Stainless Bar.

| Thyssenkrupp / Thyssenkrupp Round bar |

Outokumpu / Outokumpu Round bar / Outokumpu Latest Price | images

Mukand / Mukand steel bar |

Inconel 601 Bar buying tips

If you want to buy Inconel 601 Bar in India, Saudi Arabia, South Africa, Malaysia, Indonesia, Kuwait, UAE, Korea, Russia or anywhere in the world here are few tips to buy quality products on time:

- Always ask for Inconel 601 Bar Mill Certificate

- Check after sales service through their existing clientile, you can also buy small quantity first to check the service

- Material with ASTM standards

- Competitive price

- Beware about used / surplus material

- Beware about rejected material, you can ask for third party inspection for assured material

- Product replacement policy

- Good Packing for sea and Air transport

- For high quality choose ISO certified company

- Purchase directly from manufacturers for Competitive price & accurate materials

Inconel 601 Bar buyers

Typical buyers for Inconel 601 Bar

Inconel 601 Bar & other Nickel alloys are extensively applied in extremely corrosive conditions in the Power Industires, Chemical Industries, and Petrochemical Industries.

- Petrochemicals Plants

- Chemical Plants

- Industrial Machinery

- Power Industry

- Government Companies

Inconel 601 Bar case studies

Its about one of our client in Abu Dhabi city, we have exported 1 Ton Hot rolled bar to them in Oct, 2014, just before Diwali (India’s main Hindu festival) along with Mill certificate & third party documents, but the project chief engineer required 1 ton more Cold drawn bar on urgent basis, in our factory 99% workers & staff gone for Diwali vacation, even i was also out of town to celebrate Diwali, but when our client’s requested me that its a emergency so i immediately took a flight on the auspicious day of Diwali morning & arranged to export the material on the same day, & then i went back & celebrated Diwali at my home happily. My client was so surprised to see that because in India no one was ready to ship the materials in whole October Due to Diwali vacation, he says me thanks & sent me a special gift, i was feeling very happy that day because we works 300 days out of 365 Days but after working hard in difficult circumstances you will more enjoy in your holidays.

We have our strong network within India’s all states including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal to supply Inconel 601 Bar within 4 -12 hrs.

Inconel 601 Bar related products & stock

Why Should I Order Inconel 601 Bar From Nido Metals?

- Nido Metals is ISO certified

- Nido Metals offers overnight delivery for Inconel 601 Bar

- Professional packaging ensures that your product is received in top condition

- Our staff has in-depth product knowledge and extensive cross training. They are motivated to give you quick, accurate information-first call, every call!

- Contact us and get the right answers right away!

Why use Inconel 601 Bar

Nickel Alloys or Superalloys or High performance alloys are highly engineered to offer a superior combination of high temperature corrosion resistance, toughness, heat resistance and strength and for the most demanding applications.

- Excellent mechanical strength and creep resistance at high temperatures.

- Good surface stability.

- Corrosion and oxidation resistant.

- This category of alloys are usually sold under trade name specifications but most are listed in the Unified Numbering System. Common trade names are HASTELLOY, INCOLOY, INCONEL, NICROFER, and NIMONIC,

Inconel 601 Bar Useful Information

Super Alloy Inconel 601™ (UNS N06601)

Super alloys or high performance alloys are strengthened by performing solid-solution hardening, work hardening, and precipitation hardening. They have good creep and oxidation resistance, and consist of elements in a variety of combinations to achieve the desired result. They can be used at very high temperatures and mechanical stress, and also where high surface stability is required.

Inconel 601™ is a nickel-chromium-iron alloy having high temperature oxidation resistance. The following datasheet provides more details about Inconel 601™.

Inconel 601 Chemical Composition

The following table outlines the chemical composition of Inconel 601™.

| Element | Content (%) |

| Nickel, Ni | 58-63 |

| Chromium, Cr | 21-25 |

| Iron, Fe | 13 |

| Aluminum, Al | 1-1.70 |

| Copper, Cu | ≤ 1 |

| Manganese, Mn | ≤ 1 |

| Silicon, Si | ≤ 0.50 |

| Carbon, C | ≤ 0.10 |

| Sulfur, S | ≤ 0.015 |

Inconel 601 Physical Properties

The physical properties of Inconel 601™ are given in the following table.

| Properties | Metric | Imperial |

| Density | 8.11 g/cm3 | 0.293 lb/in3 |

| Melting point | 1349°C | 2460°F |

Inconel 601 Mechanical Properties

The mechanical properties of Inconel 601™ are displayed in the following table.

| Properties | Metric | Imperial |

| Tensile strength (solution annealed/value at room temperature) | 760 MPa | 110000 psi |

| Yield strength (@ strain 0.200%, solution annealed/value at room temperature) | 450 MPa | 65300 psi |

| Elongation at break | 42% | 42 % |

Inconel 601 Thermal Properties

The thermal properties of Inconel 601™ are highlighted in the following table.

| Properties | Metric | Imperial |

| Thermal expansion co-efficient (@20-100°C/68-212°F) | 13.75 µm/m°C | 7.639 µin/in°F |

| Thermal conductivity | 11.2 W/mK | 77.7 BTU in/hr.ft².°F |

Inconel 601 Other Designations

Other designations that are equivalent to Inconel 601™ include:

- AMS 5715

- AMS 5870

- ASTM B166

- ASTM B167

- ASTM B168

- DIN 2.4851

Inconel 601 Fabrication and Heat Treatment

Inconel 601 Machinability

Inconel 601™ can be machined using conventional machining methods which are used for iron-based alloys. Machining operations are performed using commercial coolants. High-speed operations such as grinding, milling or turning, are performed using water-based coolants. Heavy lubricants are used for tapping, drilling, boring, or broaching.

Inconel 601 Forming

Inconel 601™ is formed using all conventional techniques.

Inconel 601 Welding

Inconel 601™ is welded using gas-tungsten arc welding, gas metal-arc welding, shielded metal-arc welding, and submerged-arc welding methods.

Inconel 601 Heat Treatment

Inconel 601™ does not respond to heat treatment.

Inconel 601 Forging

Inconel 601™ is forged at 1038 to 1233°C (1900 to 2250°F)

Inconel 601 Hot Working

Inconel 601™ is hot worked at 872 to 1233°C (1600 to 2250°F)

Inconel 601 Cold Working

Inconel 601™ can be cold formed using standard tooling.

Inconel 601 Annealing

Inconel 601™ is annealed at 1149°C (2100°F). It is then cooled at temperatures ranging from 538 to 760°C (1000 to 1400°F) in order to prevent thermal cracking.

Inconel 601 Hardening

Inconel 601™ can be hardened only by cold working.

Inconel 601 Applications

Inconel 601™ is used in heat treat furnace fixtures and components such as muffles, annealing tubes, and flame shields. It can also be used in chemical process equipments which include process heaters, combustor components, and condenser tubes.

Inconel 601 hardness

Mechanical Property Requirements | |||||

|---|---|---|---|---|---|

| Ultimate Tensile | Yield Strength (0.2% OS) | Elong. in 2 in., or 50mm or 4D, min., % | R/A | Hardness | |

| Cold Worked/Annealed | |||||

| Min | 80 KSi | 30 KSi | 30 | ||

| Max | |||||

| Min | 550 MPa | 205 MPa | |||

| Max | |||||

| Hot Worked/Annealed | |||||

| Min | 80 KSi | 30 KSi | 30 | ||

| Max | |||||

| Min | 550 MPa | 205 MPa | |||

| Max | |||||

Inconel 601 machinability

MACHINABILITY RATINGS

Note that a material with a machinability rating less than 100% would be more difficult to machine than B-1112 and material with a value more than 100% would be easier.

| GRADE | APPROX. SURF. FT/MIN | % RELATIVE SPEED BASED ON B-1112 AS 100% |

| Inconel 600 | 50 | 22 |

| Inconel 625 | 20 | 12 |

| Inconel 718 | 20 | 12 |

| Inconel X-750 | 20 | 12 |

Inconel 601 p number

| P-Numbers | Base Metal (Typical or Example) |

| 43 | Nickel, Chromium, Iron – (Inconel) |

Applied Standard for Nickel Alloy Bar

| Alloy | UNS No | Bar, Rod, Wire, Forging billet, Bar billet |

| Ni-Cr-Mo Alloy | ||

| Alloy 625 | N06625 | ASTM B564, ASTM B472, ASTM B446 |

| Alloy 725 | N07725 | ASTM B637, ASTM B805 |

| Alloy 686 | N06686 | ASTM B564, ASTM B574 |

| Ni-Fe-Cr Alloy | ||

| Alloy 800 | N08800 | ASTM B564, ASTM B408 |

| Alloy 800H | N08810 | ASTM B564, ASTM B408 |

| Alloy 800HT | N08811 | ASTM B564, ASTM B408 |

| Alloy 825 | N08825 | ASTM B564, ASTM B425 |

| Alloy 925 | N09925 | ASTM B637 |

Inconel 601 Bar standard sizes & availability

| Sizes | Availability | |

| Inconel 601 Bar | 6mm |  |

| Inconel 601 Bar | 8mm |  |

| Inconel 601 Bar | 10mm |  |

| Inconel 601 Bar | 12mm |  |

| Inconel 601 Bar | 13mm |  |

| Inconel 601 Bar | 16mm |  |

| Inconel 601 Bar | 19mm |  |

| Inconel 601 Bar | 22mm |  |

| Inconel 601 Bar | 28mm |  |

| Inconel 601 Bar | 40mm |  |

| Inconel 601 Bar | 60mm |  |

| Inconel 601 Bar | 75mm |  |

| Inconel 601 Bar | 90mm |  |

| Inconel 601 Bar | 120mm |  |

Types of ASTM B166 Inconel 601 Round Bars

|

ASTM B166 Inconel 601 Bar price list

| Materials | Price Range | Unit | |||

| Inconel 600 | DIN 2.4816 | UNS N06600 | 32300-32900 | USD/Ton | |

| Inconel 601 | DIN 2.4851 | UNS N06601 | 40400-40900 | USD/Ton | |

| Inconel 625 | DIN 2.4856 | UNS N06625 | 45100-45700 | USD/Ton | |

| Inconel 718 | DIN 2.4668 | UNS N07718 | API 6A 718 | 48400-49000 | USD/Ton |

| Incoloy 800 | DIN 1.4876 | UNS N08800 | 45200-45700 | USD/Ton | |

| Incoloy 925 | UNS N09925 | 51600-52200 | USD/Ton | ||

| Incoloy 825 | DIN 2.4858 | UNS N08825 | 56500-57000 | USD/Ton | |

|

|

Specialized In Following Type Of Inconel 601 Round Bars

|  |  |

Inconel 601 Round bar | Inconel 601 Hex bar | Inconel 601 Square bar |

|  |  |

Inconel 601 Rolled Flat bar | Inconel 601 Sheared & Edged bar | Inconel 601 Half Round bar |

|  |  |

Inconel 601 Bearing Quality bar | Inconel 601 Accuracy bar | Inconel 601 Pump Shaft Quality bar |

|  |  |

Inconel 601 Bright bar | Inconel 601 Flat bar | Inconel 601 Threaded bar |

|  |  |

Inconel 601 Black bar | Inconel 601 Rod | Inconel 601 Triangle bar |

In India

Haryana, Thane, Caracas, Calgary, Pimpri-Chinchwad, Bogota, Vadodara, Singapore, Bangkok, Ranchi, Perth, Rajkot, Al Khobar, New York, Doha, Manama, Ulsan, Faridabad, Madrid, Sharjah, Kuwait City, Bengaluru, Sydney, Cairo, Algiers, Lahore, Dubai, Ludhiana, Montreal, Navi Mumbai, Jamshedpur, Visakhapatnam, Karachi, Jakarta, Ernakulam, Hanoi, Vung Tau, Moscow, La Victoria, Ahmedabad, Aberdeen, Chennai, Chiyoda, Ankara, Lagos, Atyrau, Geoje-si, Baroda, Mumbai,Dammam, Secunderabad, Howrah, Busan, Al Jubail, Petaling Jaya, Edmonton, Nashik, Ho Chi Minh City, Melbourne, Noida, Mexico City, Kanpur, Seoul, Coimbatore, Thiruvananthapuram, Chandigarh, Indore, Hyderabad, Tehran, Kuala Lumpur, Surat, Hong Kong, Houston, Granada, Dallas, Courbevoie, Port-of-Spain, Riyadh, Kolkata, Milan, Los Angeles, Jeddah, Nagpur, Pune, Toronto, Muscat, Jaipur, Gurgaon, Bhopal, New Delhi, Gimhae-si, Santiago, Rio de Janeiro, Abu Dhabi, Ahvaz, Colombo, Brisbane, Istanbul, London

Worldwide

Mongolia, Qatar, Saudi Arabia, Serbia, Lebanon, Libya, Slovakia, China, Austria, Japan, Angola, Tibet, Belgium, United Kingdom, Poland, Estonia, Romania, Russia, South Africa, Puerto Rico, Kuwait, Spain, Iran, Bahrain, Ukraine, Greece, Gabon, Azerbaijan, Bolivia, Israel, Philippines, Germany, Oman, Nigeria, Ireland, Colombia, Chile, Zimbabwe, Singapore, United Arab Emirates, Netherlands, Belarus, Australia, Poland, Thailand, Sweden, Bulgaria, Iraq, United States, Chile, Hong Kong, Mexico, Gambia, India, Brazil, Denmark, Jordan, Yemen, Argentina, Canada, Turkey, Iran, Croatia, Malaysia, Portugal,Morocco, Vietnam, Ghana, Taiwan, Namibia, Indonesia, Costa Rica, Nepal, France, Czech Republic, Egypt, Bangladesh, Trinidad & Tobago,Tunisia, Venezuela, Bhutan, Mexico, Ecuador, Norway, Sri Lanka, Peru, Kazakhstan, Pakistan, Italy, Switzerland, Finland, Lithuania, Hungary, Nigeria, South Korea, Afghanistan, Macau, New Zealand, Kenya, Algeria,

Manufacturer | Dealer | Supplier | Stockist | Distributor

Manufacturer | Dealer | Supplier | Stockist | Distributor Manufacturer | Dealer | Supplier | Stockist | Distributor

Manufacturer | Dealer | Supplier | Stockist | Distributor Manufacturer | Dealer | Supplier | Stockist | Distributor

Manufacturer | Dealer | Supplier | Stockist | Distributor Manufacturer | Dealer | Supplier | Stockist | Distributor

Manufacturer | Dealer | Supplier | Stockist | Distributor Manufacturer | Dealer | Supplier | Stockist | Distributor

Manufacturer | Dealer | Supplier | Stockist | Distributor Manufacturer | Dealer | Supplier | Stockist | Distributor

Manufacturer | Dealer | Supplier | Stockist | Distributor Manufacturer | Dealer | Supplier | Stockist | Distributor

Manufacturer | Dealer | Supplier | Stockist | Distributor