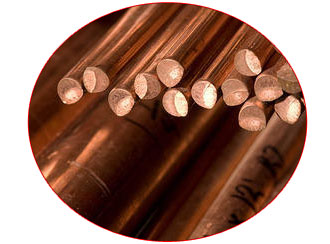

Copper Nickel Cu-Ni 90/10 (C70600) Round Bar Rod Manufacturers Suppliers in India

ASTM B151 Copper Nickel Cu-Ni 90/10 Round Bar suppliers, 90/10 Copper Nickel Round Bar Suppliers, ASTM B151 Cu-Ni 90/10 Round Bar, ASTM B151 Cu-Ni 90/10 Rod, ASTM B151 Cu-Ni 90/10 Hex Bar, ASTM B151 Cu-Ni 90/10 Flat Bar, ASTM B151 Cu-Ni 90/10 Angles,c70600 Round Bar suppliers, ASTM B151 Cu-Ni 90/10 Bright round bar, ASTM B151 Cu-Ni 90/10 square bar, ASTM B151 Cu-Ni 90/10 hexagon bar

UNS C70600 Cu-Ni Flat Bar Exporter,90/10 Copper Nickel Round Bar Suppliers,c70600 Round Bar Suppliers,Cupronickel 90/10 Round Bar Suppliers, Cu-Ni 90/10 Square Bars Leading Manufacturers,Cupro Nickel 90/10 Hexagon Bar, Cu-Ni 90/10 Black Bar, Cu-Ni C70600 Forged Bar,Cu-Ni 90/10 Rod Manufacturers & Suppliers in India

Nido Metals is an ISO 9001:2008 certified Manufacturer and Suppliers of finished steel bright bars in the domestic as well as Global market. Since 1982 the company has the most elaborate and sophisticated manufacturing infrastructure to produce cold drawn Copper Nickel Cu-Ni 90/10 (C70600) Round Bar, We have a Production capacity of 6000 MT of HIGH PRECISION QUALITY STEEL BRIGHT BARS in different grades, sizes & sections.

The company plant is equipped with a range of machines and advanced processing facilities that give tremendous flexibility to meet the exact needs of our clients.

The company is the foremost producer of Bright bars in India which compare with the finest in the world. We process almost all popular grades in various national and International specifications.we are producing Bright Steel Bars in a variety of shapes and sizes according to various specifications of steel, and conforming to BSS, EN series, SAE, ISI, DIN, AISI.

ASTM B151 Cu-Ni 90/10 Bright flat bar, ASTM B151 Cu-Ni 90/10 Peeled & Polished Bar, ASTM B151 Cu-Ni 90/10 Hexangular Bar/Rod,90/10 Copper Nickel Round Bar Suppliers,c70600 Round Bar Suppliers,Cupronickel 90/10 Round Bar Suppliers, ASTM B151 Cu-Ni 90/10 Roll Bar, ASTM B151 Cu-Ni 90/10 Cold Rolled Bright Bar, ASTM B151 Cu-Ni 90/10 Triangle Bar, ASTM B151 Cu-Ni 90/10 shaped bar,ASTM B111 Copper Nickel 90 / 10 Bright Bar,Cupronickel 90/10 Round Bar Suppliers, Cu-Ni DIN 2.0872 Hex Bar, Cu-Ni 90/10 Cold Finished Bar Suppliers in India

ASTM B151 Copper Nickel Cu-Ni 90/10 Round Bar Specifications

| Grade | DIN | UNS |

| Copper Nickel 90-10 | 2.0872 | C70600 |

| Grade | : | Cu-Ni 90/10 (C70600), UNS C71640 |

| Range | : | 5 mm To 500 mm thick in 100 mm TO 6000 mm |

| Related Specifications | Mechanical Properties | |||||||

| Alloy Name | BS | UNS | BS EN | Others | Ultimate Tensile Strength N/mm² | Minimum Yield Strength N/mm² | Elongation % | Hardness HB |

| Copper Nickel 90/10 | CN102 | C70600; C70610 | CW352H | 2.0872 | 280 | 105 | 27 | 70-120 |

AISI Copper Nickel Cu-Ni 90/10 Round Bars Specification

Length : 100 mm to 3660 mm Long

Other Grade : 17-4PH, 15.5 PH,

Material Grade : AISI/SAE 4140, 4130, 4340, 8620, 8640

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Our Copper Nickel Cu-Ni 90/10 Round Bars conforms to NACE MR0175/ISO 15156

Dimension : EN, DIN, JIS, ASTM, BS, ASME, AISI

Specification : ASTM B111 / ASME SB111

Range : 5 mm To 500 mm thick in 100 mm TO 6000 mm

Copper Nickel 90/10 Round Bars Range : 6 mm to 120 mm.

Copper Nickel 90/10 Square Bars Range : 10 mm to 200 mm.

Copper Nickel Cu-Ni 90/10 Round Bars Mechanical & Physical Properties

| Density | Melting Point-Liquidus | Min.Tensile (KSI) | Min.Yield (KSI) | Elongation |

| 0.323 lb/in3 at 68 F | 2100 F | 38 | 15 | 30% |

ASTM B111 Cupro Nickel Cu-Ni 90/10 (C70600) Bars Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

| Copper Nickel 90-10 | 2.0872 | C70600 |

Copper Nickel Cu-Ni 90/10 Round, Bright, Hex, Threaded Bar Chemical Composition

| Grade | Cu | Pb | Fe | Zn | Ni | Mn |

| Copper Nickel 90/10 | 88.6 min | .05 max | 1.8 max | 1 max | 9-11 max | 1.0 max |

Types Of Available Products ASME, ASTM, EN, BS, GB, Copper Nickel 90 / 10 Round Bars Live Inventory

» B111 Cupro Nickel 90-10 Polish Bars Manufacturer

» AISI C70600 (90/10) Black Bars Distributors

» Top Quality High Copper Nickel 90 / 10 Spring Steel Bars

» Copper Nickel 90 / 10 Bright Bar Exporter

» Cupro Nickel 90 / 10 Rods

» Copper Nickel 90 / 10 Round Bars

» ASTM B111 Cu- Ni 90/10 (C70600) Bars

» Copper Nickel UNS C70600 Round Bars

» C70600 Cu-Ni (90/10) Rods Manufacturer

» Standard ASTM B111 Copper Nickel (C70600) Forged Round Bars

» High Speed Copper Nickel 90/10 Hollow Bar Suppliers

» ASME, ASTM, EN, BS, GB, Copper Nickel C70600 Flat Bars

» Copper Nickel 90 / 10 (C70600) Round Bar

» Copper Nickel 90/10 Threaded Bars Stockiest in India

» Cu-Ni 90 / 10 Cold Drawn & Polished Square Bars

» Austenitic ASTM Bright Cu-Ni (C70600) Bar

» Copper Nickel DIN 2.0872 Round Bars

» AISI Cu-Ni 90/10 (C70600) Hexagon Bars Dealers

» Standard ASTM B111 Cu-Ni 90 / 10 Cold Drawn Bars Stockholder

» Cold Rolled Cupro Nickel 90 / 10 Rods

ASTM B151 C70600

Copper-Nickel-Zinc Alloy & Copper-Nickel Rod & Bar

This specification establishes the requirements for copper-nickel-zinc and copper-nickel rod and bar for general application produced from Copper Alloy UNS Nos. C70600.

ASTM B151 C70600 Chemical Composition (Typical)

| Element |

| Limits |

|

| min | max |

|---|---|---|

| Copper, Incl. Silver | Remainder | |

| Nickel, Incl. Cobalt | 9.000 | 11.000 |

| Lead | 0.000 | 0.050 |

| Iron | 1.000 | 1.800 |

| Manganese | 0.000 | 1.000 |

| Zinc | 0.000 | 1.000 |

| Phosphorus | 0.000 | 0.020 |

| Sulphur | 0.000 | 0.020 |

| Carbon | – | – |

ASTM B151 C70600 Mechanical Properties (Typical)

| Parameter | Temper | Value |

| Tensile ksi, Min | H01 | – |

| Tensile ksi, Min | H04 | 60 |

| Tensile ksi, Min | M30 | 38 |

| Tensile ksi, Min | O60 | 38 |

| Yield 0.2 % ksi, Min | H01 | – |

| Yield 0.2 % ksi, Min | H04 | 38 |

| Yield 0.2 % ksi, Min | M30 | 15 |

| Yield 0.2 % ksi, Min | O60 | 15 |

| Grain Size, mm | OS015 | 0.015 – 0.03 |

| Grain Size, mm | OS035 | 0.025-0.050 |

| Grain Size, mm | OS070 | – |

| Elongation, Min | H01 | – |

| Elongation, Min | H04 | 10 |

| Elongation, Min | M30 | 30 |

| Elongation, Min | O60 | 30 |

Types of Copper Nickel Cu-Ni 90/10 Round Bar:

| • | Round, |

| • | Square, |

| • | Hex (A/F), |

| • | Bush, |

| • | Rectangle, |

| • | Flat, |

| • | Wire Mesh |

Applications:

Electronics

Transport and traffic

Pulp and paper industry

Medicine

Fertilizers

Valve & Pumps

Petrochemical

Architecture and construction

Aerospace

Nuclear Power

Energy industry

Chemicals industry

Nickel Alloy in Pulp and Paper

Motor industry

Food and drink

Bars – Round, Squares, Hexagon, Octagonal, Flat, Shapes

Rod – Round, Squares, Hexagon, Octagonal, Flat, Shapes

Key Features

- High ductility and toughness

- Excellent resistance to erosion and corrosion in seawater

- Inherent resistance to biofouling

- Excellent fabrication and welding properties

- Retention of mechanical properties down to cryogenic temperatures

ASTM B151 Copper Nickel Cu-Ni 90/10 Round Bar weight calculations

Test Certificate

Mill Test Certificate as per EN 10204 / 3.1B

Why Buy a Full Bar When You Just Need a Small Volume?

The Group, through its steel-making plant and rolling mills, focuses on the production of steel product ranging from bars to rods serving mainly the construction and engineering sectors. Our production and inventories consists of copper nickel, copper nickel 90/10, cupro nickel 70/30, stainless steel bar, hot rolled carbon and alloy flats, Round Bar, Bright Bar, Square Bar, Hex Bar, Flat Bar, Rectangular Bar,Black Bar, Threaded Bar, Forged Bar, Rod sharp cornered squares, and special sections. These products are exported to countries such as Singapore, Indonesia, Brunei, Myanmar, China, Hong Kong, Australia, Fiji, New Zealand, Papua New Guinea, Mauritius, Maldives, Sri Lanka, Pakistan, South Africa, Madagascar, Egypt, UAE, Amman, Kuwait, Bahrain, United Kingdom, Denmark, Switzerland and Germany. We are staffed by a team of well-trained technical personnel, providing technical support and services relating to quality and applications of our products. Our technical team is able to advise on the most appropriate product quality to meet your requirements. Our specialty is to provide wide range of Copper Nickel 90/10 Bar with no minimum order.

Copper Nickel 90/10 Bar specification

| Copper Nickel 9010 Bar (Rod) & Wire | |||||

| Sr. No. | Material | Diameter | Length | Specification | Manufacturer |

| 1 | Copper Brass Aluminium Phosphorus Bronze Gun Metal Lead | Rod Bar: 5 mm to 200 mm | 100 mm to 3660 mm Long | IS BS ASTM ASTM B151 | |

| Wire : 50 Swg. to 4 Swg. | |||||

| Note:- | ||

| Copper Brass Phosphorus Bronze Gun Metal Lead | In Grade | 99.99% (Rolled – Hot & Cold, Electrolytic & Commercial) Extruded & Drawn Free Cutting, Naval Brass, 60/40 Brass, Forging Brass PB2, 90/10 Etc. 90/10, 70/30 Etc. 99.95 to 99.99% |

| Other Grade | Zinc, Bi-Metals, Leaded Etc. Copper Alloy, Brass Alloy, Aluminium Alloy Etc. | |

| Form | Round, Square, Hex (A/F), Bush, Rectangle, Wire (Coil Form), Wiremesh, Block, Billet, Ingot, Casting, Forging Etc. | |

| Hardness | Soft, Hard, Half Hard, Quarter Hard Etc. | |

| Value Added Service | Casting, Forging, Machining, Heat Treatment, Annealed, Pickled, Polish, Anodising, Rolling, Cutting, Bending, Minor Fabrication Etc. | |

| Test Certificate | Laboratory Test Certificate From Govt. Approved Laboratory. | |

| Specialize | Copper E/c Grade (High Conductivity) Casting & Forging for Bar & Bush (with Alloy) | |

Copper Nickel 90/10 Round Bar

| Manufacturer | Dealer | Supplier | Stockist | Distributor Trade Name: Copper Nickel 9010 Bar Round bar weight calculationsMost common Copper Nickel round bar grades include:

Test Certificate

|

Copper Nickel 90/10 Bright Bar

| Manufacturer | Dealer | Supplier | Stockist | Distributor Trade Name: Copper Nickel 9010 Bar Most common Copper Nickel round bar grades include:

Test Certificate

|

Copper Nickel 90/10 Square Bar

| Manufacturer | Dealer | Supplier | Stockist | Distributor Trade Name: Copper Nickel 9010 Bar Square bar weight calculatorMost common Copper Nickel Square Bar grades include:

Test Certificate |

Copper Nickel 90/10 Hex Bar

|

Trade Name: Copper Nickel 9010 Bar Most common Copper Nickel Hex Bar grades include:

Test Certificate |

Copper Nickel 90/10 Rectangle Bar / Rectangular Bar

|

Trade Name: Copper Nickel 9010 Bar Most common Copper Nickel Rectangle Bar grades include:

Test Certificate |

Copper Nickel 90/10 Flat Bar

|

Standard : ASTM / ASME SA A582, A276, A564, ASTM A484, 484M Most common Copper Nickel Flat Bar grades include:

Test Certificate

|

Copper Nickel 90/10 Black Bar

|

Trade Name: Copper Nickel 9010 Bar Most common Copper Nickel Black Bar grades include:

Test Certificate |

Copper Nickel 90/10 Threaded Bar

|

Trade Name: Copper Nickel 9010 Bar Most common Copper Nickel Threaded Bar grades include:

Test Certificate |

Copper Nickel 90/10 Forged Bar

|

Trade Name: Copper Nickel 9010 Bar Most common Copper Nickel Forged Bar grades include:

Test Certificate |

Copper Nickel 90/10 Rod

|

Trade Name: Copper Nickel 9010 Bar Most common Copper Nickel Rod grades include:

Test Certificate |

Copper Nickel 90/10 Bar leading manufacturers

We are distributor, dealer & supplier of Outokumpu round bar, Stainless steel bar, Thyssenkrupp round bar, Steel bar, Mukand Ltd Round Bar. You can also download the PDF file of Outokumpu stainless steel bar sizes and specifications, Outokumpu stainless steel bar brochure, Stainless Steel Bar and Long Products, European Stainless Bar and A Machining Comparison between Outokumpu PRODEC® and Standard Stainless Bar.

| Thyssenkrupp / Thyssenkrupp Round bar |

Outokumpu / Outokumpu Round bar / Outokumpu Latest Price | images

Mukand / Mukand steel bar |

Copper Nickel 90/10 Bar buying tips

If you want to buy Copper Nickel 9010 Bar in India, Saudi Arabia, South Africa, Malaysia, Indonesia, Kuwait, UAE, Korea, Russia or anywhere in the world here are few tips to buy quality products on time:

- Always ask for Copper Nickel 9010 Bar Mill Certificate

- Check after sales service through their existing clientile, you can also buy small quantity first to check the service

- Material with ASTM standards

- Competitive price

- Beware about used / surplus material

- Beware about rejected material, you can ask for third party inspection for assured material

- Product replacement policy

- Good Packing for sea and Air transport

- For high quality choose ISO certified company

- Purchase directly from manufacturers for Competitive price & accurate materials

Copper Nickel 90/10 Bar buyers

Typical buyers for CuNi10Fe1Mn Copper Nickel:

AUTOMOTIVE: Power Steering Tube, Brake Lines

CONSUMER: Screw Lamp Bases

INDUSTRIAL: Condenser Plates, Condensers, Weld Torch Tips, Heat Exchanger Tubes, Valve Bodies, Evaporator Tubes, Pressure Vessels, Distiller Tubes, Pump Impellers for Oil Refining, Ferrules, Evaporators

MARINE: Boat Hulls, Tube Sheet for Salt Water Service, Salt Water Pipe Fittings, Salt Water Piping Systems, Salt Water Piling Wrap, Hot Water Tanks, Salt Water Baffles, Propeller Sleeves, Ship Hulls, Water Hoses

PLUMBING: Flanges

Copper Nickel 9010 Bar case studies

Its about one of our client in Abu Dhabi city, we have exported 1 Ton Hot rolled bar to them in Oct, 2014, just before Diwali (India’s main Hindu festival) along with Mill certificate & third party documents, but the project chief engineer required 1 ton more Cold drawn bar on urgent basis, in our factory 99% workers & staff gone for Diwali vacation, even i was also out of town to celebrate Diwali, but when our client’s requested me that its a emergency so i immediately took a flight on the auspicious day of Diwali morning & arranged to export the material on the same day, & then i went back & celebrated Diwali at my home happily. My client was so surprised to see that because in India no one was ready to ship the materials in whole October Due to Diwali vacation, he says me thanks & sent me a special gift, i was feeling very happy that day because we works 300 days out of 365 Days but after working hard in difficult circumstances you will more enjoy in your holidays.

We have our strong network within India’s all states including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal to supply Copper Nickel 90/10 Bar within 4 -12 hrs.

Copper Nickel 90/10 Bar related products & stock

Why Should I Order Copper Nickel 9010 Bar From Nido Metals?

- Nido Metals is ISO certified

- Nido Metals offers overnight delivery for Copper Nickel 9010 Bar

- Professional packaging ensures that your product is received in top condition

- Our staff has in-depth product knowledge and extensive cross training. They are motivated to give you quick, accurate information-first call, every call!

- Contact us and get the right answers right away!

Why use Copper Nickel 9010 Bar

-

Copper-Nickel alloy Copper 90/10 and Copper 70/30

- Outstanding resistance to corrosion, particularly sea water

- 70/30 is stronger and has superior resistance to impingement corrosion

- Good resistance to biofouling, with the 90/10 alloy being slightly superior compared to the 70/30 alloy

Copper rich alloys are:

- Ductile

- Can be hardened only by cold working

- Good corrosion resistance

- Good strength

- Low temperature co-efficient of electrical resistance

Copper Nickel 9010 Bar Useful Information

CuNi 90/10 Copper Nickel

ASTM B151, MIL C15726F

Offers excellent corrosion resistance, especially in marine salt water environments. The main, wrought copper-nickel alloys chosen for sea water service contain 10 or 30 percent nickel. They also have important additions of iron and manganese which are necessary to maintain good corrosion resistance. Some common applications for copper nickel include: valves, pump components, fittings, flanges and various other marine hardware components.

Copper nickel alloys are alloys that have moderate strength and thermal stability in high temperature levels. The high oxidation resistance of these alloys is visible in moist air and steam. Copper nickel alloys have 2 to 30% nickel, high oxidation resistance and stress corrosion cracking resistance.

Copper nickel alloys have good fabricability and high inherent resistance to biofouling. The addition of manganese, niobium, iron and or chromium in these alloys improves their corrosion resistance and strength.

Nickel is soluble in copper and this renders the copper nickel alloys as single phase alpha structures. The cast structures have alpha dendrites that contain huge quantities of nickel. The dendrite structure is broken by mechanical treatments. However, the alloying elements do not become homogenized even by repeated thermal and mechanical treatments.

Copper nickel alloys are of two types that include 90/10 and 70/30. The 90/10 alloys are widely used as they are inexpensive. The 90/10 copper nickel alloys have great resistance to sea water corrosion due to the presence of significant amounts of manganese and iron.

Copper nickel alloys are used in the following applications:

- Hydraulic lines

- Fish cages for aquaculture

- Heat exchangers and condensers

- Desalination units

- Sea water pipework

- Tubes for power plants and ships

- Offshore fire water systems

- Pumps, valves, sheathing and fittings for ship hulls

The following datasheet will provide details about UNS C70600 copper nickel alloys.

CuNi 90/10 Chemical Composition

The chemical composition of UNS C70600 copper nickel alloys is outlined in the following table.

| Element | Content (%) |

| Cu | 88.7 |

| Fe | 1.3 |

| Ni | 10.0 |

CuNi 90/10 Physical Properties

The following table shows the physical properties of UNS C70600 copper nickel alloys.

| Properties | Metric | Imperial |

| Density | 8.94 g/cm3 | 0.323 lb/in3 |

CuNi 90/10 Mechanical Properties

The mechanical properties of UNS C70600 copper nickel alloys are displayed in the following table.

| Properties | Metric | Imperial |

| Tensile strength, ultimate | 303-414 MPa | 43900-60000 psi |

| Tensile strength, yield (depending on temper) | 110-393 MPa | 16000-57000 psi |

| Elongation at break (in 254 mm) | 42.00% | 42.00% |

| Machinability (UNS C36000 (free-cutting brass) = 100%) | 20% | 20% |

| Shear modulus | 52.0 GPa | 7540 ksi |

| Poisson’s ratio | 0.34 | 0.34 |

| Elastic modulus | 140 GPa | 20300 ksi |

CuNi 90/10 Other Designations

Equivalent materials to UNS C70600 copper nickel alloys are:

| ASME SB111 | ASTM B111 | ASTM B466 | ASME SB171 |

| ASME SB359 | ASTM B122 | ASTM B469 | MIL T-22214 |

| ASME SB395 | ASTM B151 | ASTM B543 | SAE J461 |

| ASME SB466 | ASTM B171 | ASTM B608 | SAE J463 |

| ASME SB467 | ASTM B359 | DIN 2.0872 | MIL T-16420 |

| ASME SB543 | ASTM B395 | MIL C-15726 | MIL T-15005 |

| ASTM B432 |

CuNi 90/10 Fabrication and Heat Treatment

CuNi 90/10 Annealing

UNS C70600 copper nickel alloys are annealed at temperatures between 593 and 816°C (1100 and 1500°F)

CuNi 90/10 Cold Working

UNS C70600 copper nickel alloys have good cold working capacity.

CuNi 90/10 Hot Working

Copper nickel 90/10 alloys have good hot forming capacity.

CuNi 90/10 Welding

Copper nickel 90/10 alloys can be welded using gas shielded arc welding, spot welding, coated metal arc welding, butt welding, oxyacetylene welding, brazing, soldering and seam welding processes.

CuNi 90/10 Forging

Temperatures between 843 and 954°C (1550 and 1750°F) are suitable for the forging of 90/10 copper nickel alloys.

CuNi 90/10 Machinability

The machinability rating of copper nickel 90/10 alloys is 20%.

CuNi 90/10 Applications

UNS C70600 copper nickel alloys are used in areas where stainless steel cannot be used due to chloride stress-corrosion cracking and in other parts requiring high levels of corrosion resistance. These alloys are also used as machined and forged valve and pump parts that are utilized for seawater services.

Copper Nickel 9010 Bar standard sizes & availability

| Sizes | Availability | |

| Copper Nickel 9010 Bar | 6mm |  |

| Copper Nickel 9010 Bar | 8mm |  |

| Copper Nickel 9010 Bar | 10mm |  |

| Copper Nickel 9010 Bar | 12mm |  |

| Copper Nickel 9010 Bar | 13mm |  |

| Copper Nickel 9010 Bar | 16mm |  |

| Copper Nickel 9010 Bar | 19mm |  |

| Copper Nickel 9010 Bar | 22mm |  |

| Copper Nickel 9010 Bar | 28mm |  |

| Copper Nickel 9010 Bar | 40mm |  |

| Copper Nickel 9010 Bar | 60mm |  |

| Copper Nickel 9010 Bar | 75mm |  |

| Copper Nickel 9010 Bar | 90mm |  |

| Copper Nickel 9010 Bar | 120mm |  |

Copper Nickel 9010 Bar price list

|

|

In India

Kolkata, Baroda, Visakhapatnam, Kuala Lumpur, La Victoria, Dammam, Brisbane, Muscat, Hong Kong, Doha, Petaling Jaya, Faridabad, Rio de Janeiro, Haryana, New Delhi, Milan, Melbourne, Los Angeles, Seoul, Gimhae-si, Lagos, Noida, Howrah, Kuwait City, London, Bhopal, Vung Tau, Dubai, Gurgaon, Calgary, Granada, Moscow, Surat, Port-of-Spain, Ulsan, Edmonton, Caracas, Sharjah, Algiers, Navi Mumbai, Istanbul, Ahvaz, Jeddah, Atyrau, Vadodara, Colombo, Hanoi, Chiyoda, Bogota, Ho Chi Minh City, Dallas, Mumbai, Ahmedabad, Lahore, Jamshedpur, Ankara, Secunderabad, Nashik, Ludhiana, Indore, Karachi, Manama, Hyderabad, Busan, Rajkot, Singapore, Montreal,Tehran, Ernakulam, Abu Dhabi, Perth, Bengaluru, Thane, Pimpri-Chinchwad, New York, Houston, Jakarta, Toronto, Thiruvananthapuram, Pune, Al Jubail, Courbevoie, Aberdeen, Bangkok, Al Khobar, Madrid, Geoje-si, Sydney, Coimbatore, Jaipur, Chennai, Mexico City, Santiago, Chandigarh, Riyadh, Cairo, Ranchi, Kanpur, Nagpur,

Worldwide

Japan, Taiwan, Peru, Ecuador, Ghana, Netherlands, Bulgaria, Namibia, Philippines, Belarus, Ukraine, Puerto Rico, Ireland, Kazakhstan, Chile, Iran, Russia, Azerbaijan, Zimbabwe, Turkey, Austria, Vietnam, Italy, Malaysia, Australia, Mongolia, India, Bhutan, Pakistan, Nigeria, Finland, Estonia, Hungary, United Kingdom, Brazil, Lithuania, Oman, Colombia, Morocco, Iraq, Yemen, South Africa, Costa Rica, Thailand,Canada, Tibet, Greece, Venezuela, New Zealand, Portugal, Norway, Trinidad & Tobago,Tunisia, China, Nigeria, Egypt, France, Nepal, Hong Kong, Spain, South Korea, Czech Republic, Bangladesh, Sri Lanka, Macau, Kenya, Romania, Poland, Mexico, Jordan, Libya, Belgium, Afghanistan, Algeria, Israel, United Arab Emirates, United States, Croatia, Germany, Bolivia, Gabon, Singapore, Serbia, Lebanon, Switzerland, Saudi Arabia, Argentina, Slovakia, Sweden, Kuwait, Qatar, Indonesia, Denmark, Bahrain, Chile, Angola, Gambia

Manufacturer | Dealer | Supplier | Stockist | Distributor

Manufacturer | Dealer | Supplier | Stockist | Distributor Manufacturer | Dealer | Supplier | Stockist | Distributor

Manufacturer | Dealer | Supplier | Stockist | Distributor Manufacturer | Dealer | Supplier | Stockist | Distributor

Manufacturer | Dealer | Supplier | Stockist | Distributor Manufacturer | Dealer | Supplier | Stockist | Distributor

Manufacturer | Dealer | Supplier | Stockist | Distributor Manufacturer | Dealer | Supplier | Stockist | Distributor

Manufacturer | Dealer | Supplier | Stockist | Distributor Manufacturer | Dealer | Supplier | Stockist | Distributor

Manufacturer | Dealer | Supplier | Stockist | Distributor Manufacturer | Dealer | Supplier | Stockist | Distributor

Manufacturer | Dealer | Supplier | Stockist | Distributor